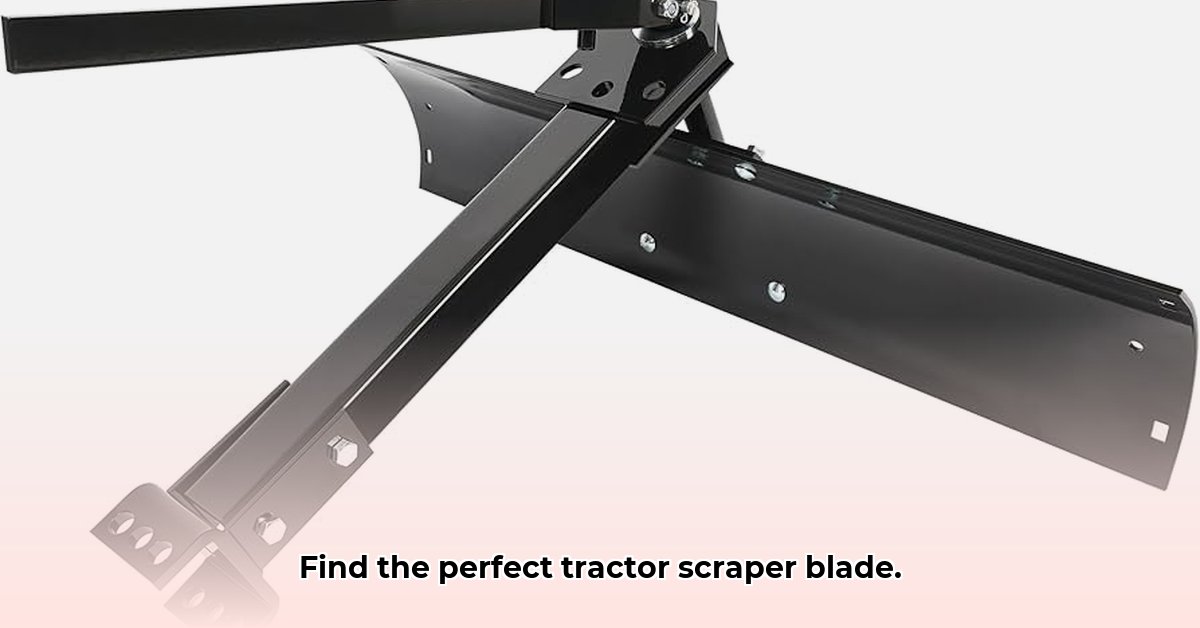

Choosing the right tractor scraper blade—whether a box scraper or a land plane—is crucial for efficient farm management. This guide helps you select, maintain, and troubleshoot these vital tools. We'll cover types, features, selection criteria, maintenance, and manufacturer comparisons to ensure a worthwhile investment. For more options, check out this guide on small tractor plows.

Understanding Scraper Blade Types and Their Applications

Before selecting a blade, consider its primary use. Different blades excel in specific tasks:

- Leveling and Smoothing: Box scrapers, with their rigid box design, provide precise control for fine grading and creating level surfaces. Think of them as precision landscaping tools for your fields.

- Material Movement: Standard blades are versatile workhorses for shifting soil, gravel, or other materials. Their robust design handles various jobs.

- Snow Removal: Rubber-edged blades protect paved surfaces, while heavy-duty steel blades tackle packed snow and ice. The choice depends on your winter conditions.

Types of Tractor Scraper Blades

Several blade types cater to diverse needs and soil conditions:

- Standard Blades: These vary in size and material. Steel offers durability for tough jobs; poly blades are gentler on paved surfaces. Wider blades cover more ground but are less maneuverable. Consider your field size and layout.

- Box Scrapers: Designed for precision leveling and grading, box scrapers often feature adjustable scarifiers (small metal teeth) that break up compacted soil. Many include hydraulic adjustments for on-the-fly angle and depth changes, increasing efficiency.

Choosing the Right Scraper Blade: A Step-by-Step Guide

Choosing the right blade involves a methodical approach:

Assess Your Needs: What's the primary application? Leveling, material movement, or snow removal? How much area needs covering daily or weekly? This dictates blade size and type.

Analyze Your Soil: Soil type significantly impacts blade choice. Soft soil requires a less aggressive blade than hard, compacted soil. Consider the presence of rocks which could damage a less robust blade.

Set Your Budget: Prices vary widely based on size, features, and brand. Establish a budget aligning with your needs and financial capabilities.

Research Manufacturers: Compare specifications, read online reviews (a valuable source of user experience), and investigate delivery lead times to avoid project delays.

Test Drive (If Possible): Whenever possible, test different blades in your soil conditions to assess their handling and suitability before making a purchase. This hands-on assessment is invaluable.

Maintaining Your Scraper Blade: A Guide to Longevity

Proper maintenance ensures your blade's longevity and performance:

- Regular Lubrication: Keep moving parts lubricated according to the manufacturer's recommendations. This minimizes wear and tear. Refer to your owner's manual for specific guidance.

- Sharpening Blades: Sharpen or replace worn blades promptly. Dull blades reduce efficiency and increase tractor strain. A sharp blade dramatically improves performance.

- Proper Storage: Store your blade in a dry environment to prevent rust and damage. Proper storage significantly extends blade lifespan.

Manufacturer Comparison: A General Overview (Note: Specific pricing and lead times are subject to change and vary by location)

| Manufacturer | Approximate Lead Time (Weeks) | Hydraulic Adjustment? | Approximate Price Range ($) | Notable Features |

|---|---|---|---|---|

| Brand A | 4-6 | Yes | 1500-3000 | Heavy-duty, wide working width, strong reputation |

| Brand B | 8-12 | No | 1000-2000 | Durable, often more affordable |

| Brand C | 2-4 | Yes | 2000-4000 | Precise adjustments, advanced features |

Troubleshooting Common Problems

Addressing common issues promptly prevents downtime and ensures optimal performance:

Blade Doesn't Engage: Check hydraulic fluid levels and inspect lines/hoses for leaks. If the problem persists, consult a qualified mechanic.

Blade Wears Too Quickly: Sharpen or replace the blade. This could also indicate improper use or a lower-quality blade.

Hydraulic Problems: Do not attempt DIY repairs on hydraulic issues. Engage a qualified mechanic to address these problems. Regular maintenance is preventative.

Conclusion: Investing in Efficiency

Choosing a high-quality, well-maintained scraper blade is a strategic investment. By following these steps, you optimize your farm's efficiency and minimize potential problems. Remember, the best blade matches your specific needs and receives consistent maintenance.